Maximizing Business Potential with CNC Prototype China: A Comprehensive Guide for Metal Fabricators

In the rapidly evolving landscape of modern manufacturing, the ability to produce precise, reliable prototypes and components is paramount. CNC prototype China has emerged as a game-changing technology that drives efficiency, innovation, and competitiveness for metal fabricators and manufacturing enterprises worldwide. As a leading industry player, DeepMould exemplifies how adopting advanced CNC prototyping solutions can transform business operations, enhance product quality, and accelerate time-to-market.

Understanding CNC Prototype China: A Cornerstone of Modern Manufacturing

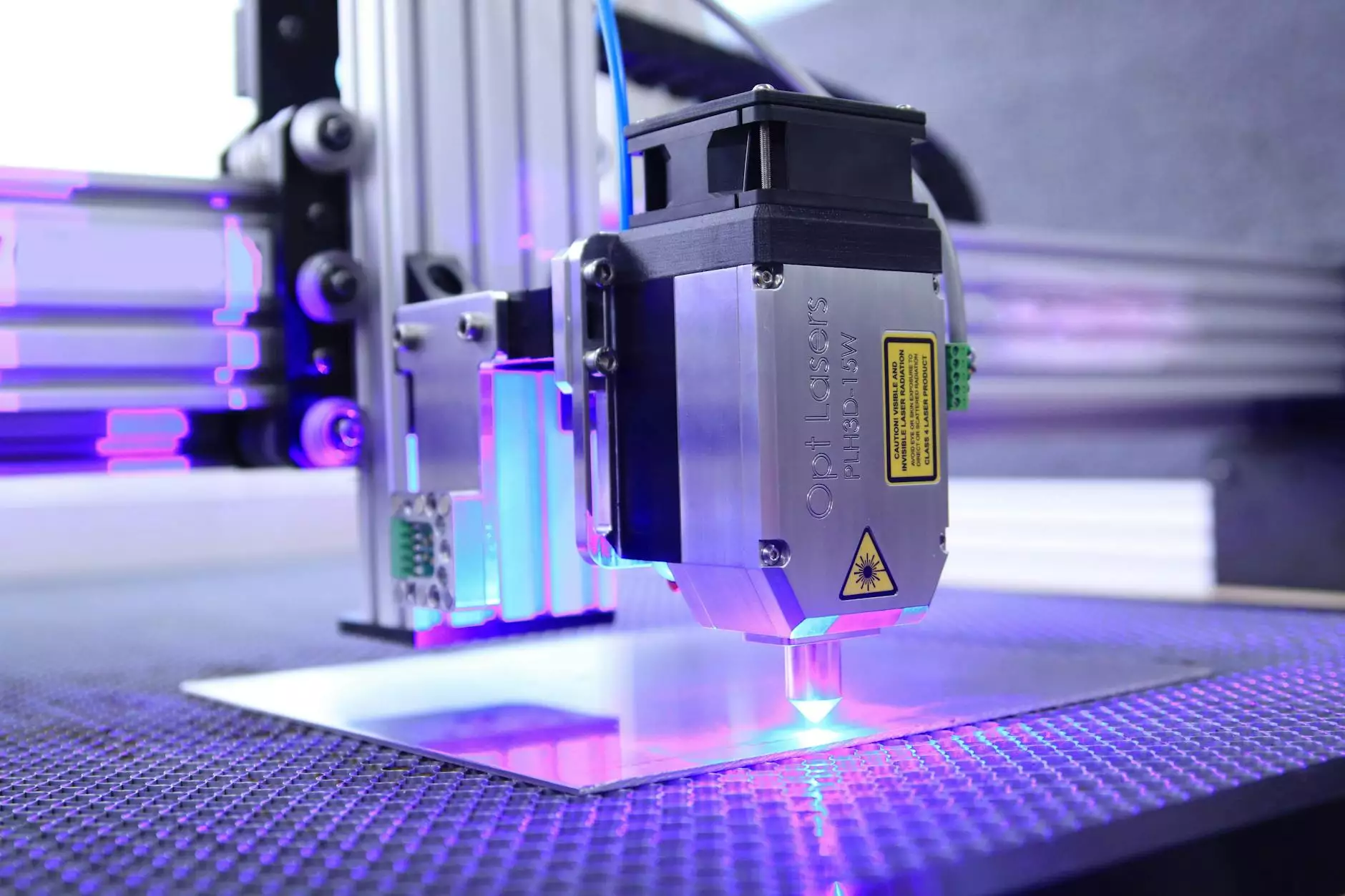

Computer Numerical Control (CNC) machining involves the use of computer-controlled machine tools to produce complex, high-precision parts from various materials, especially metals. The term CNC prototype China refers to the manufacturing of prototype components within China utilizing cutting-edge CNC technology. This approach offers a *cost-effective* alternative without compromising on quality or precision.

China's manufacturing industry has invested heavily in CNC technology, creating a robust ecosystem of skilled engineers, state-of-the-art machines, and streamlined processing capabilities. As a result, businesses worldwide benefit from CNC prototype China by accessing high-quality prototypes at significantly reduced costs, faster turnaround times, and with exceptional consistency.

The Advantages of CNC Prototype China for Metal Fabricators

1. Superior Precision and Consistency

CNC machining allows for tolerances as tight as ±0.01 mm, enabling the production of highly detailed and complex prototypes. This precision guarantees that early-stage prototypes accurately reflect final product specifications, reducing costly revisions and iterations later in the development process.

2. Cost-Effectiveness and Scalability

Thanks to China's mature supply chain infrastructure, CNC prototype China offers competitive pricing for both small batch and large-scale production. Metal fabricators can benefit from economies of scale, lowering manufacturing costs and increasing profit margins.

3. Accelerated Production Cycles

The advanced CNC equipment and experienced technicians in China facilitate rapid prototype development, with lead times often shorter than traditional manufacturing countries. Faster prototyping enables companies to expedite product testing, validation, and overall time-to-market.

4. Material Versatility

CNC prototype China can work with a broad range of metals, including aluminum, brass, stainless steel, copper, titanium, and various alloys, providing flexibility to meet diverse project requirements.

5. High-Quality Surface Finishes and Tolerances

Modern CNC machinery achieves exceptional surface finishes suitable for aesthetic appeal and functional performance. This reduces the need for additional finishing processes, saving time and costs.

Why Choose DeepMould for Your CNC Prototype Needs in China?

- Industry-Leading Expertise: DeepMould boasts decades of experience in CNC manufacturing and metal fabrication, ensuring projects meet the highest standards.

- Advanced Technology: Our state-of-the-art CNC machines, including multi-axis mills and lathes, enable complex prototype fabrication with unmatched accuracy.

- Quality Assurance: Rigorous inspection and quality control protocols guarantee every prototype adheres to strict specifications.

- Comprehensive Service Range: From rapid prototyping to small batch production, DeepMould provides end-to-end solutions tailored to your business needs.

- Cost Optimization: Our supply chain and manufacturing efficiencies enable competitive pricing, maximizing your ROI.

How the CNC Prototype China Process Elevates Your Business

Step 1: Design and Engineering Collaboration

Our team works closely with clients during the initial design phase, utilizing CAD/CAM software to optimize part design for CNC manufacturing. This collaborative approach ensures manufacturability, reduces errors, and prepares the design for efficient production.

Step 2: Material Selection and Preparation

Choosing the right material is critical for prototype functionality and durability. DeepMould provides expert guidance on material selection, considering factors such as strength, weight, corrosion resistance, and cost.

Step 3: Precision CNC Machining

The part manufacturing begins with high-precision CNC machining in our China facilities. Our machines operate with ultrafine precision, and our technicians monitor every process to ensure accuracy and surface quality.

Step 4: Inspection and Quality Control

Each prototype undergoes meticulous inspection using coordinate measuring machines (CMM) and other advanced tools. This guarantees that prototypes meet specified tolerances and quality standards.

Step 5: Delivery and After-Sales Support

Once approved, prototypes are packaged securely and delivered promptly worldwide. Our support doesn’t end there — we stand ready to assist with revisions, additional prototyping, or transitioning to mass production.

Applications of CNC Prototype China in Metal Fabrication Industries

Modern metal fabricators leverage CNC prototype China across a wide spectrum of industries, including:

- Automotive: Rapid prototyping of engine components, chassis parts, and custom fixtures.

- Aerospace: Precision metal parts and complex geometries vital for safety and performance.

- Medical Devices: Custom surgical instruments, implants, and testing prototypes.

- Electronics: Enclosures, connectors, and intricate mechanical parts.

- Industrial Machinery: Custom fixtures, tooling, and prototype assemblies for testing machinery designs.

Key Factors Contributing to the Success of CNC Prototype China in Business

- Strategic Supply Chain Networks: China's extensive manufacturing network ensures raw materials, components, and machinery are readily available and cost-effective.

- Skilled Workforce: A large pool of highly trained engineers and technicians specializing in CNC machining guarantees production quality and innovation.

- Investment in Technology: Continuous upgrades to CNC equipment enable manufacturers like DeepMould to stay at the forefront of precision engineering.

- Quality Management: Strict adherence to international standards (ISO, CE, etc.) ensures high-quality output for global clients.

- Customer-Centric Approach: Tailored solutions, flexible production runs, and excellent after-sales service build long-term partnerships.

Environmental and Sustainability Aspects of CNC Manufacturing in China

China's CNC manufacturing industry is increasingly emphasizing sustainable practices, including waste reduction, energy efficiency, and environmentally friendly materials. Leading companies like DeepMould implement eco-conscious operations to align with global sustainability goals, helping clients achieve responsible manufacturing.

Future Trends in CNC Prototype China and Metal Fabrication

1. Adoption of Automation and AI

The integration of artificial intelligence and automation in CNC machining promises smarter, more adaptive manufacturing processes, reducing human error and increasing productivity.

2. Enhanced Materials and Finishes

Research into new alloys and surface treatments will expand the capabilities of CNC prototypes, creating lighter, stronger, and more durable components.

3. Customization and On-Demand Manufacturing

The trend toward personalized products will see greater demand for flexible CNC prototyping services, allowing rapid customization for niche markets.

4. Digital Twin and IoT Integration

Utilizing digital twin technology and IoT connectivity will enable real-time monitoring, predictive maintenance, and optimization of CNC manufacturing processes.

Conclusion: Elevate Your Business with Reliable CNC Prototype China Partner

In today’s fast-paced, innovation-driven market, leveraging CNC prototype China is essential for metal fabricators seeking to maintain a competitive edge. Through high precision, cost efficiency, rapid turnaround, and extensive material options, China’s CNC solutions empower businesses to bring their ideas to life swiftly and accurately.

Partnering with a reputable provider like DeepMould ensures access to state-of-the-art technology, expert engineering support, and comprehensive service that meets international standards. Embracing CNC prototype China is not just a strategic move; it’s a pathway to sustained growth, innovation, and business success.

Start Your Journey Toward Manufacturing Excellence Today

To capitalize on the advantages of CNC prototype China and elevate your business, explore DeepMould’s tailored solutions designed specifically for metal fabricators. Whether you need prototypes for testing, design validation, or pre-production, our expert team is ready to assist you in achieving manufacturing excellence.

Contact us today to learn more about how our CNC prototyping services can unlock your business’s full potential and help you stay ahead in a competitive global market.