Shell and Tube Heat Exchanger Calculations

Welcome to AceTeknik, your reliable partner in the realm of home services. As leading contractors in the field of plumbing, we strive to provide our clients with the best solutions for their needs. In this comprehensive article, we will dive deep into shell and tube heat exchanger calculations and shed light on this crucial aspect of thermal energy management.

Understanding Shell and Tube Heat Exchangers

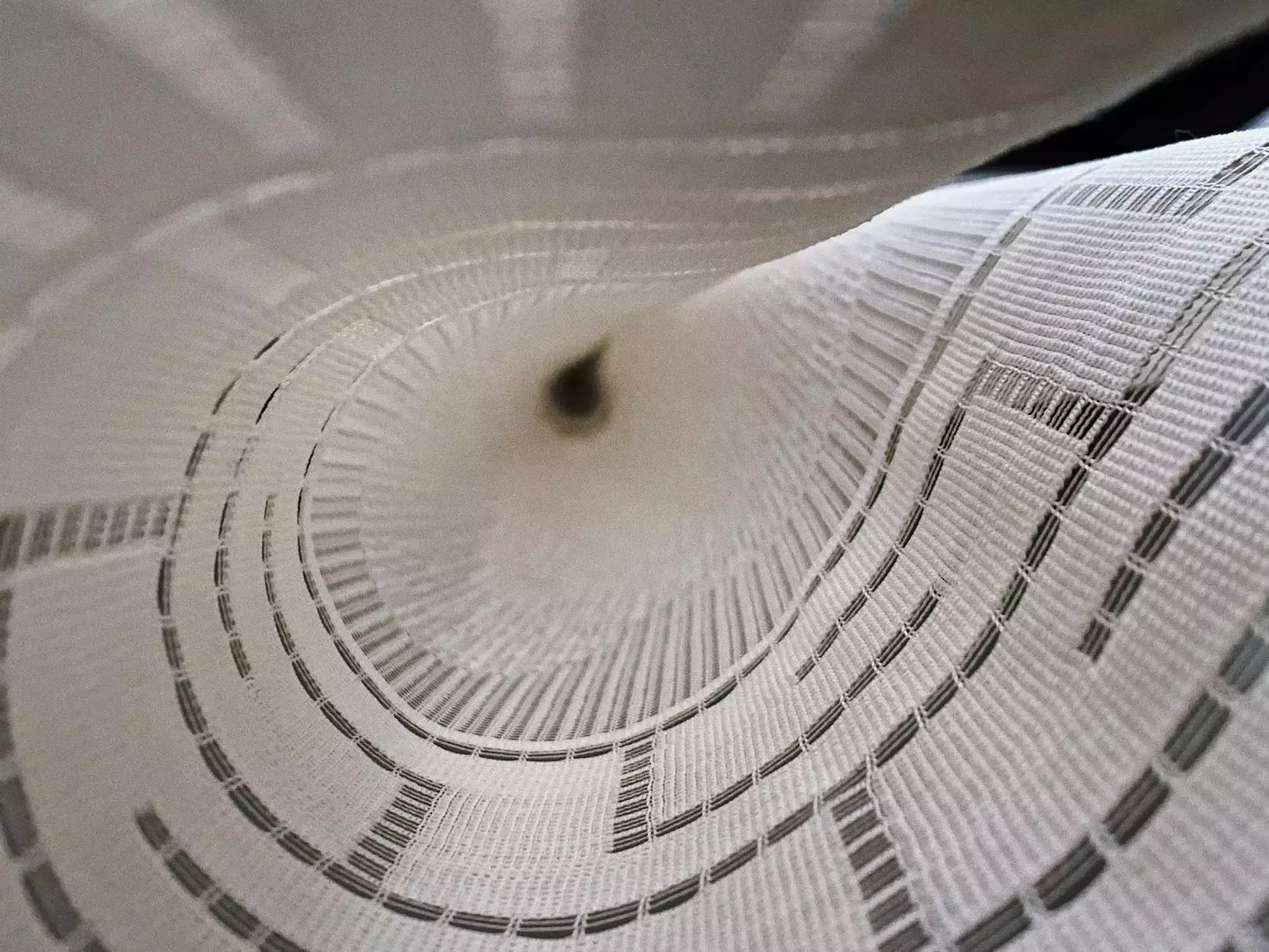

A shell and tube heat exchanger is a vital component used in various industries to transfer heat between two fluid streams. It consists of parallel tubes enclosed within a cylindrical shell. One fluid flows through the tubes (the tube side) while the other fluid is directed around the tubes within the shell (the shell side). The interaction between these fluids allows for efficient heat transfer.

These heat exchangers are widely utilized due to their versatility, reliability, and efficiency. They find applications in heating, ventilation, air conditioning (HVAC) systems, power plants, chemical processes, petroleum refineries, and many other industries where heat transfer is essential.

The Importance of Shell and Tube Heat Exchanger Calculations

Accurate calculations play a critical role in designing and optimizing shell and tube heat exchangers. By understanding the calculations involved, engineers can determine the heat transfer rate, pressure drop, and overall performance of these systems. These calculations help in selecting the appropriate dimensions, materials, and design configuration to achieve desired results.

1. Heat Transfer Rate

The heat transfer rate, expressed in terms of Watts or British Thermal Units per hour (BTU/hr), determines the amount of heat exchanged between the fluids within the heat exchanger. It depends on factors such as the temperature difference between the inlet and outlet of each fluid, the flow rate, and the surface area available for heat transfer.

2. Pressure Drop

Pressure drop refers to the decrease in pressure as the fluid flows through the heat exchanger. It is important to consider because excessive pressure drop can significantly affect the overall system performance. Calculating pressure drop aids in selecting appropriate pipe sizes, layouts, and optimizing flow velocities to minimize energy loss.

3. Fluid Properties and Fouling

Fluid properties, such as density, viscosity, specific heat capacity, and thermal conductivity, play a crucial role in heat exchanger calculations. Engineers need to consider these properties to accurately determine heat transfer coefficients and overall system performance. Fouling, the accumulation of deposits on heat exchanger surfaces, also impacts calculations and necessitates periodic maintenance to ensure optimal heat exchanger efficiency.

Calculating Heat Transfer Coefficients

Heat transfer coefficients are crucial parameters used in shell and tube heat exchanger calculations. They represent the efficiency of heat transfer between the fluids. Calculations involve determining both the inside and outside heat transfer coefficients, considering factors such as the nature of fluids, flow velocities, tube geometry, and materials of construction.

Various methods, including the Kern Method, Bell-Delaware Method, and Log Mean Temperature Difference (LMTD) method, are employed to calculate heat transfer coefficients. These methods, combined with empirical correlations and industry standards, allow engineers to obtain accurate results and design optimal heat exchangers for specific applications.

Benefits of AceTeknik's Expertise in Shell and Tube Heat Exchanger Calculations

At AceTeknik, we pride ourselves on our expertise in shell and tube heat exchanger calculations. Our team of experienced professionals possesses in-depth knowledge of the science behind heat transfer and can provide you with the highest quality engineering solutions.

By entrusting your heat exchanger calculations to us, you can benefit from:

- Accurate Design: We utilize advanced software simulation tools and industry benchmarks to ensure precise calculations and optimal design for your shell and tube heat exchangers.

- Performance Optimization: Our thorough heat transfer calculations help identify potential bottlenecks and areas of improvement, allowing us to optimize performance and enhance energy efficiency.

- Cost Reduction: With our expertise, we can identify cost-effective solutions without compromising performance, enabling you to achieve the desired results within budget.

- Compliance and Safety: Our calculations adhere to industry standards and regulations, promoting safety and ensuring compliance with necessary codes and guidelines.

- Reliable Support: As your trusted partner, we provide ongoing support and maintenance services to ensure your heat exchangers operate optimally throughout their lifecycle.

Contact AceTeknik Today for Your Shell and Tube Heat Exchanger Needs

When it comes to home services, contractors, and plumbing, AceTeknik sets the standard for excellence. Our expertise in shell and tube heat exchanger calculations ensures that you receive the most reliable and efficient solutions for your thermal energy management needs.

For personalized advice and to discuss your specific requirements, contact us today at [email protected] or give us a call at +1234567890. Our team of professionals is ready to assist you in any way possible.

Trust AceTeknik, the true experts in shell and tube heat exchanger calculations, to help you achieve optimal system performance and maximize energy efficiency.